To find out more, click on the brochure below or contact us to arrange for a meeting.

What is Proactive Maintenance?

Proactive Maintenance enables operators to perform maintenance when necessary only and to avoid unnecessary steps before that, making maintenance more systematic. It also prevents unnecessary downtime of equipment as it helps to resolve problems before they become failures, identify the root causes of failures and can help to extend the lifetime of equipment and reduce downtime as such result of sudden machine failure.

The initial tool in order to predict and plan maintenance tasks is the collection of data during equipment operation and to compare and analyse data variations over time to make justifications and decide for maintenance stops at the right time.

Proactive maintenance programs are frequently supported by Computerized Maintenance Management Systems (CMMS) for integrated data collection in order to support the consistent condition monitoring.

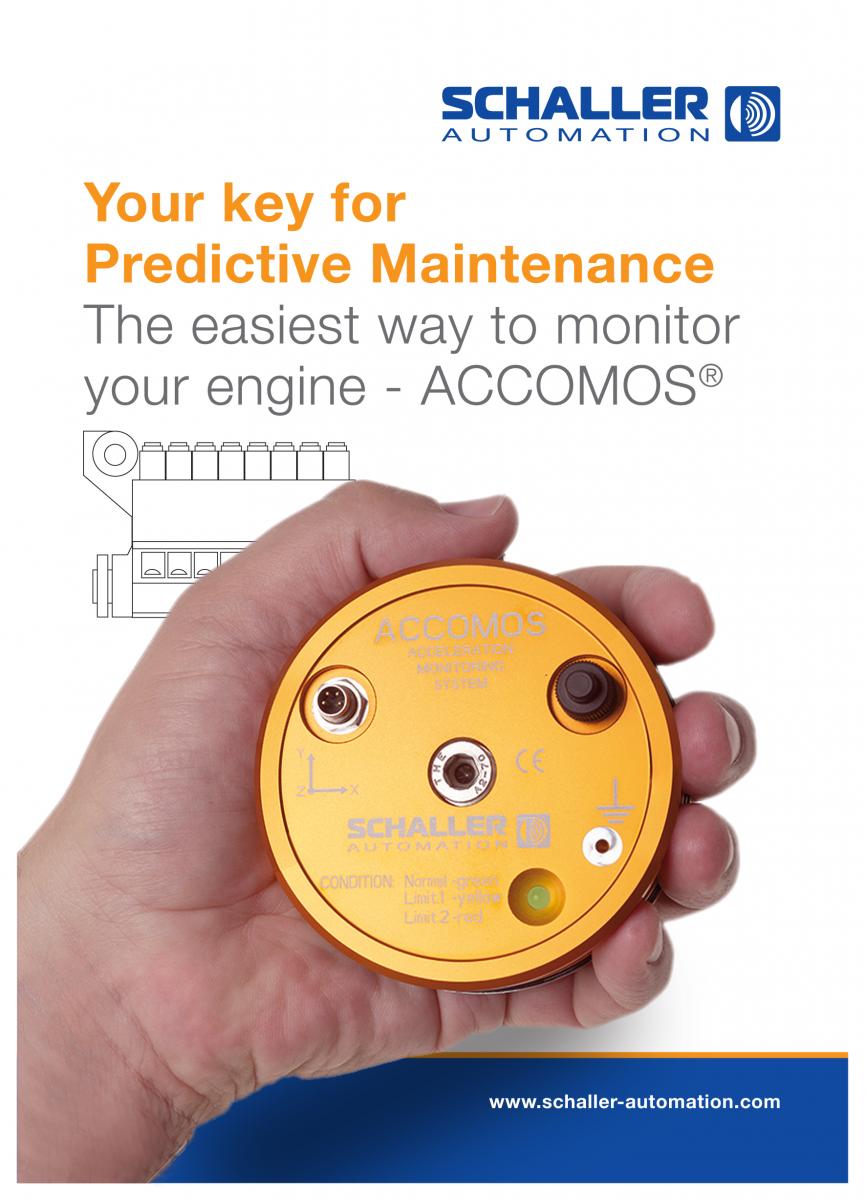

But whichever strategy is followed, Schaller Automation has the answer for individual or computerized monitoring to support your maintenance approaches and program implementations in the most efficient way possible.